Wesley Chapel’s Guide to Commercial Pump Installation

For businesses and developers in the rapidly growing Wesley Chapel and Temple Terrace areas, securing a reliable water source and distribution system is fundamental. Whether for irrigation, industrial processes, HVAC systems, fire suppression, or potable water supply, commercial pump systems are often the backbone of operations. Wesley Chapel’s Guide to Commercial Pump Installation provides essential insights into the planning, selection, and installation process for these critical systems, ensuring they meet performance demands and regulatory standards.

Unlike residential setups, commercial pump installations involve larger capacities, higher demands, and often more complex configurations. Proper installation by experienced professionals is crucial not only for operational efficiency but also for safety, longevity, and compliance with local codes and regulations. A poorly installed system can lead to premature failure, costly downtime, and potential hazards.

Phase 1: Planning and System Design

Successful commercial pump installation begins with meticulous planning and design. This phase is critical for ensuring the final system meets the specific needs of the Wesley Chapel or Temple Terrace facility. Key considerations include:

- Defining Water Requirements: Accurately determine the required flow rate (gallons per minute, GPM) and pressure (pounds per square inch, PSI). This depends on the application – irrigation systems have different needs than manufacturing processes or multi-story building water supplies. Factor in peak demand periods.

- Water Source Assessment: Identify the water source – a private well, a surface water body (requiring specific permits), or boosting pressure from a municipal supply. If using a well, its yield capacity must be confirmed (pump test).

- Site Evaluation: Assess the installation site, considering space availability, accessibility for maintenance, power supply location, environmental conditions (potential flooding, temperature extremes), and noise considerations.

- Regulatory Compliance: Identify all applicable building codes, health regulations, environmental permits (especially for surface water or large well withdrawals via SWFWMD), and safety standards (e.g., NFPA codes for fire pumps).

- System Configuration: Design the layout, including pipe sizing (critical for minimizing friction losses), valve locations, control strategy (e.g., constant speed, VFD, pressure tanks), and necessary filtration or treatment.

Engaging engineers and experienced pump installation contractors like Accurate Drilling Solutions early in the planning phase is highly recommended.

Selecting the Right Commercial Pump

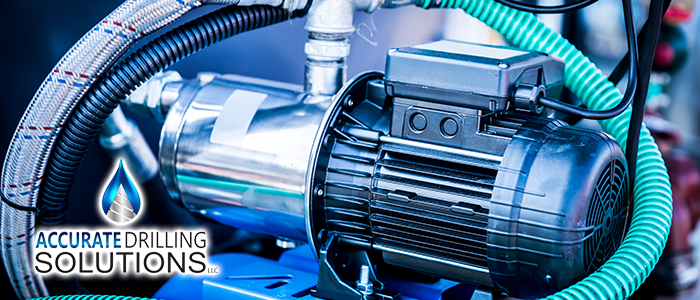

Choosing the appropriate pump is vital. The selection depends heavily on the flow rate, pressure requirements (Total Dynamic Head – TDH), water source characteristics, and the nature of the fluid being pumped. Common types of pumps used in commercial applications include:

Centrifugal Pumps: Widely used for clean water applications. Sub-types include end-suction, split-case, and vertical multi-stage pumps, each suited for different pressure and flow ranges.

Submersible Pumps: Typically used in deep wells but also for sumps and booster applications. Motor and pump are a single unit submerged in the fluid.

Turbine Pumps: Often used for high-capacity wells (vertical turbine) or as booster pumps (inline turbine).

Positive Displacement Pumps: Used for specific applications involving high pressures or viscous fluids (less common for basic water supply).

Key selection criteria include pump performance curves (matching required flow/head), efficiency ratings (NPSHr vs. NPSHa), materials of construction (compatibility with water quality), motor specifications (voltage, phase, enclosure type), and reliability/maintenance requirements. Consulting pump manufacturer data and working with knowledgeable suppliers or contractors is essential.

The Installation Process: Best Practices

Proper installation techniques are critical for the longevity and performance of commercial pump systems. This goes beyond simply connecting pipes and wires. Best practices include:

Foundation: Ensure a solid, level foundation (typically concrete) to support the pump and motor, minimizing vibration.

Alignment (for base-mounted pumps): Precise alignment between the pump and motor shafts is crucial to prevent premature bearing and seal failure. Laser alignment tools are often used.

Piping Connections: Support piping independently; it should not strain the pump casing. Use appropriate flanges or couplings. Install isolation valves on suction and discharge for maintenance. Install check valves on the discharge to prevent backflow. Suction piping should be short, direct, and properly sized to prevent cavitation, as outlined by resources like the Pumps & Systems Magazine technical articles.

Electrical Wiring: All wiring must comply with the National Electrical Code (NEC) and local regulations. Use correctly sized wires, conduits, and motor starters/protection devices (overload relays, phase monitors for 3-phase). Ensure proper grounding.

Control System Integration: Install pressure switches, sensors, VFDs, and control panels according to design specifications and manufacturer instructions. Ensure controls are protected from weather and physical damage.

Priming (for non-submersible pumps): Ensure the pump casing and suction line are completely filled with water before initial start-up to prevent damage.

Only qualified technicians should perform the installation.

Incorporating Variable Frequency Drives (VFDs)

For many commercial applications in Wesley Chapel, especially those with varying water demand, incorporating VFDs during installation offers significant advantages. VFDs control pump speed to precisely match demand, leading to:

Energy Savings: Reduced speed drastically cuts energy consumption compared to constant-speed pumps throttling flow with valves.

Constant Pressure Control: VFDs can maintain consistent system pressure, improving performance for many applications.

Soft Start/Stop: Gradual ramp-up and ramp-down reduces electrical inrush current and mechanical stress on the pump, motor, and piping (minimizing water hammer).

Extended Equipment Life: Reduced wear and tear on bearings, seals, and motors due to smoother operation.

While VFDs add initial cost, the energy savings and operational benefits often provide a rapid return on investment. Proper VFD programming and integration during installation are key to realizing these benefits.

Commissioning and Testing

After the physical installation is complete, the commissioning phase is crucial. This involves systematically checking all components and testing the system’s operation:

Pre-Start Checks: Verify rotation direction of the motor, check lubrication levels, confirm all valves are in the correct positions, ensure the system is primed.

Initial Start-Up: Monitor motor amperage, voltage, system pressure, and flow rate during start-up. Check for leaks, excessive noise, or vibration.

Performance Verification: Operate the system across its expected range (if possible) and verify that it meets the design flow and pressure requirements. Adjust control settings (pressure switch setpoints, VFD parameters) as needed.

Safety System Checks: Test safety features like overload protection, low/high pressure cutoffs, and emergency stops.

Documentation: Record all commissioning data, including operating parameters, settings, and any adjustments made. Provide comprehensive manuals and documentation to the owner/operator.

Thorough commissioning ensures the system is operating correctly, safely, and efficiently before being put into regular service.

Partnering with Experienced Installers

Given the complexity and criticality of commercial pump systems, partnering with an experienced and licensed installation company is paramount. Accurate Drilling Solutions has the expertise to handle Wesley Chapel’s Guide to Commercial Pump Installation projects, from initial design consultation through expert installation and commissioning.

Experienced installers understand local codes in Wesley Chapel and Temple Terrace, possess the necessary tools and diagnostic equipment, and follow industry best practices. They can help select the right equipment, ensure proper installation techniques are used, and provide reliable post-installation support and maintenance services. Investing in professional installation minimizes risks and maximizes the return on your pump system investment.

Conclusion: Ensuring Reliable Water Operations in Wesley Chapel

A properly designed and installed commercial pump system is essential for seamless operations in Wesley Chapel and Temple Terrace businesses and developments. From careful planning and equipment selection to meticulous installation and thorough commissioning, every step matters. Incorporating modern technologies like VFDs can further enhance efficiency and performance. Adhering to best practices and regulatory requirements ensures a reliable, safe, and long-lasting system.

For expert commercial pump installation, service, and maintenance tailored to the demands of your business, trust the professionals at Accurate Drilling Solutions. Visit Accurate Drilling Solutions to learn how we can support your commercial water system needs.

continue reading

Related Posts

Sarasota Commercial Pump Maintenance Essentials For commercial properties in Sarasota

Plant City Agricultural Well Systems: A Complete Guide Agriculture is

St. Petersburg’s Guide to Sustainable Water Solutions In coastal communities